Proven Quality

The Pinnacle of Quality Construction

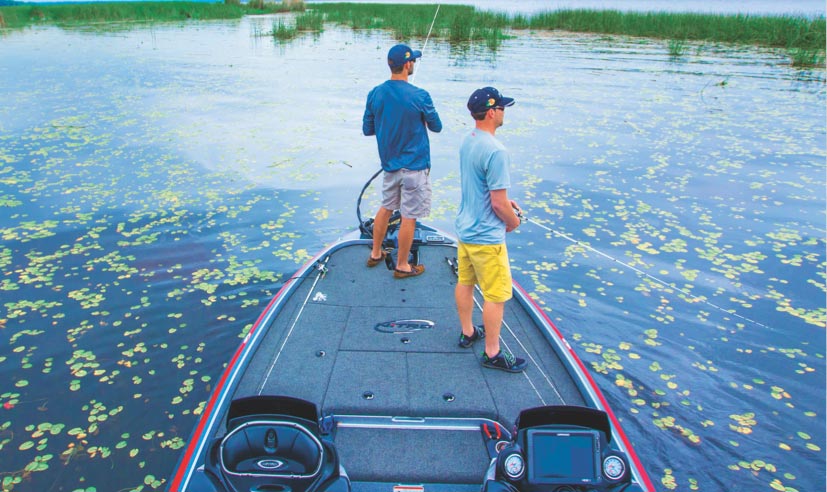

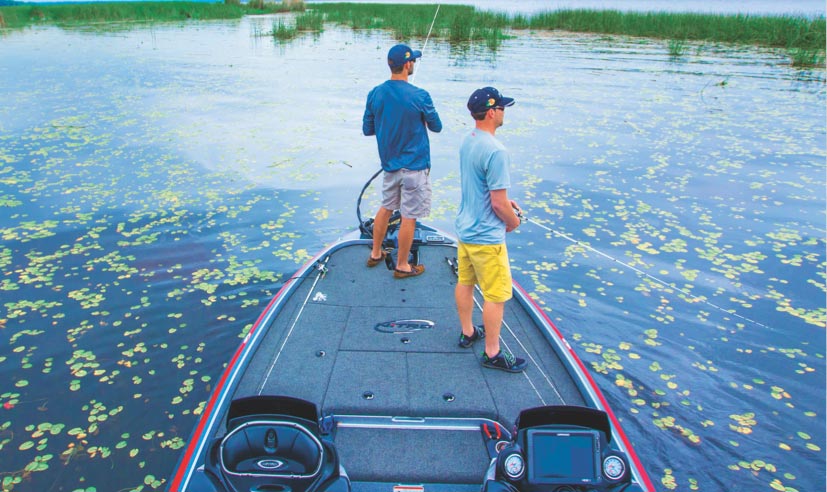

Every NITRO® performance boat is built with such care and dedication to quality that you can see it in the fit and finish, feel it in the smooth ride and count on it for a lifetime. Thanks to the skill and experience of our master team of fiberglass craftspeople, care is taken at every step in the process to ensure the finest, longest-lasting boat at the best price. These fast, comfortable and highly-fishable boats are designed to help you be the best angler you can be, whether you're competing in an Elite tournament or just relaxing over a weekend at the lake.

Quality Designed and Built with Care

Designed to the Highest Standards of Quality

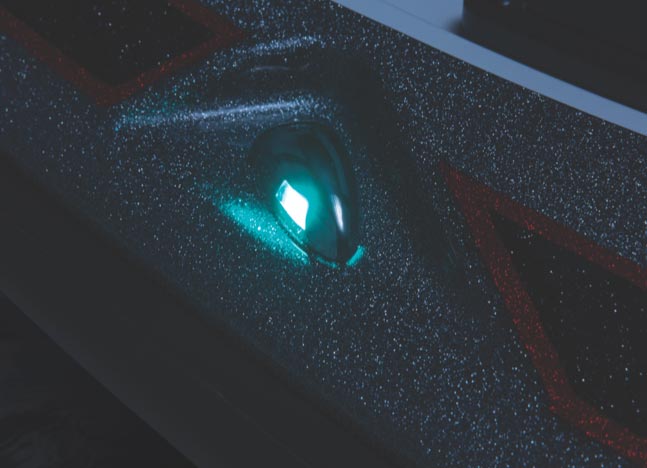

From the moment a new NITRO boat model or feature enhancement is brought to light, every step taken by our designers and engineers is carefully planned to ensure the resulting product performs to exceed expectations. NITRO quality is easy to see when you look at a model up close—from tight tolerances and carpeted compartment interiors to the deep, rich colors of our gelcoat that highlight the smooth and durable curves of the NVT hull. NITRO boats are manufactured efficiently, resulting in minimal waste and producing a quality boat and peace of mind for our customers.

Repeat Industry CSI Awards

NITRO Boats has been recognized eight years in a row for excellence in customer satisfaction by the National Marine Manufacturers Association (NMMA). This means that hundreds of feedback surveys, returned by actual purchasers of NITRO fiberglass fishing boats, reported average satisfaction ratings above 90 points on a scale of 100.

The CSI award from NMMA is a tribute to our skilled and dedicated boat makers and to the thousands of people in our company and dealer network who provide support to our customers. By working hard and working smart, they are delivering the promise of quality and value that has placed NITRO Boats solidly among the leaders in performance fishing boats.

Lean Sigma Methods

Continuous Improvement for Increased Quality

We manufacture our boats using Lean Sigma principles—the same method used by the world's leading automobile, aerospace and medical companies. Lean Sigma practices allow us to manufacture boats more efficiently, producing less waste and more consistent results, to give you a premium quality boat and the peace of mind that comes with it. And our culture of continuous improvement means that we're always looking for ways to make the process and our boats better.

Rugged Construction

Built Tough to Reliably Compete and Win

Hand-laid fiberglass hulls are built with engineered, woven fiberglass fabric for strength and chopped fiberglass strand for puncture resistance, and then a custom-molded liner is bonded to the hull to provide longitudinal and transverse supports to the running surface. Extra-thick, molded knee supports reinforce the transom to hold outboards and shallow-water anchors.

1. Gelcoated Stringer/Liner System

The one-piece system is double-bonded to the hull to produce a unitized structure for strength and durability.

2. Transom Supports

Transom knee supports (part of the stringer/liner system) provide maximum support for the transom.

3. Unitized Structure

The deck and hull are chemically bonded 360 degrees and mechanically fastened with stainless steel fasteners every 6".

4. Foam-Filled Stringer

The stringer/liner system and other cavities in the hull are filled with foam for superior safety, noise reduction and level flotation if swamped.

5. Maximized Fuel Capacity

The fuel tank is strategically placed for maximum fuel capacity and better stability and tracking.

6. Contoured Balsa Decking

This allows us to achieve the best weight-to-strength ratio to assure you a lifetime of boating adventures.